The applications within industry 4.0 are numerous. This use case demonstrates this. By collecting and analysing the right data, a certain process can be improved and with the predictions of our algorithms, the right actions can be taken.

In this case, we deal with an urgent issue of a steel manufacturer; one of their most critical production installations had come to a stop. It turned out that there was a lack of lubrication in a gearbox, which led to a standstill of the entire production line.

Find Root cause

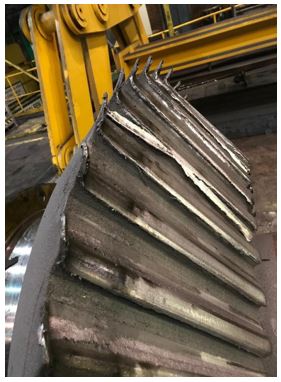

The unpleasant part of the situation was that the failure of the lubrication system could cause several other machines to stop working at any time. An investigation into the cause showed that the blockage, in this case, was caused by an unidentified substance in the pipes, probably originating from a previous maintenance job. Many of the pipes were also found to be corroding and this was causing clogging at key points in the lubrication system. In addition, it appeared that there was no real-time insight into the effectiveness of the lubrication of the assets. Although the lubrication system looked healthy during daily checks, in reality no oil was reaching the gears. The photo below shows the damage to the gear.

Intelligent sensors are the solution

Now that the cause of the standstill was clear, the gear could be repaired and the lubrication put into order. But it is better to prevent downtime in the future. To do that, you need data that allows you to make predictions about the effectiveness of the lubrication system using the right algorithms. There are various techniques that can be used to achieve this. The most obvious is the use of conventional flow meters. Unfortunately, the purchase and installation of flow meters for such a large system is extremely expensive. In addition, the lead time for such a capex project is often too long.

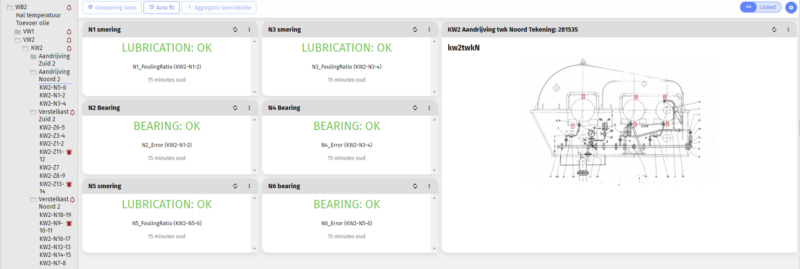

Perfact came up with a better solution and, in collaboration with Yokogawa, placed over 200 IIoT sensors on various assets. Together with smart algorithms and alarms, the system provides information about the effectiveness of lubrication and collects it in one dashboard. The dashboard contains the plant’s asset hierarchy, making it easy to find specific lubrication points. The main dashboard can be clicked through to the lowest level of the individual instrument. The entire project was implemented in a few weeks and later the algorithms were fine-tuned

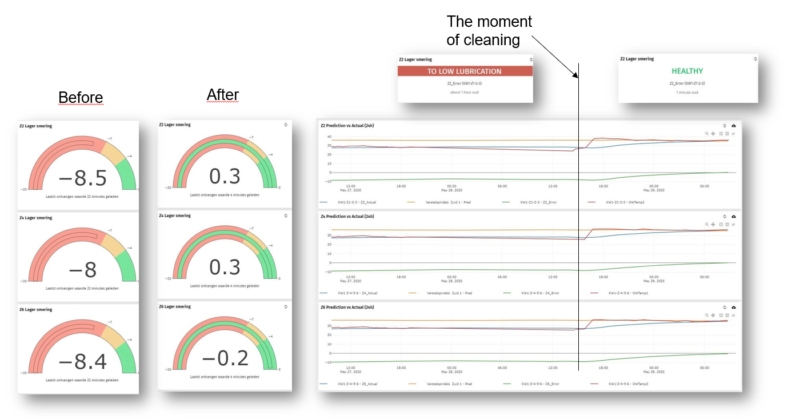

After starting the dashboard, there were immediate warnings indicating a lot of dirt in the pipes. After cleaning the pipes, the indicators turned green again. This was the ultimate proof that the algorithms were working as intended. The image below illustrates the trends and predictions for three of the lubrication points.

Predictive data leads to results

Based on the information made available by the IIoT sensors and the algorithms that display predictive values, the client can act. Cleaning of specific pipelines is now effectively applied and reduces the risks of unplanned failures and thus also extends the lifespan of the assets. The added value per breakdown that is prevented amounts to more than EUR 800,000. The system also helps to prioritise cleaning actions during planned stops and thus to manage time and risk for the maintenance crew.

By applying industry 4.0, we make the difference for our client in terms of asset performance, budget and process improvement. A win-win situation in all respects.